Water Purifier For Well Water - Truths

Table of ContentsThe Buzz on Water Purifier For Well WaterThe Ultimate Guide To Water Purifier For Well WaterThe Buzz on Water Purifier For Well WaterThe Water Purifier For Well Water Ideas

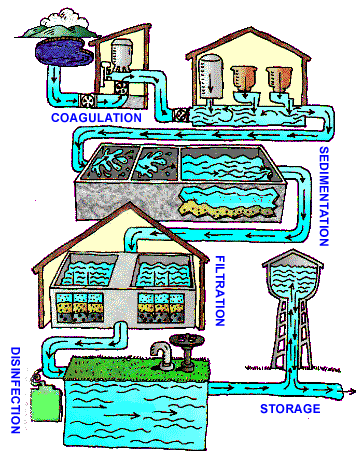

A phosphorous substance is included to assist manage corrosion of pipelines. This aids prevent lead as well as copper that might exist in pipes from leaching right into the water. As the water leaves the plant, ammonia is contributed to change the chlorine to chloramine, an anti-bacterial that maintains a recurring in the circulation system against bacterial contamination.All chemicals that are included are licensed food quality, safe for use in foods. Dealt with water is stored in deep below ground storage tanks and likewise flows by gravity to pumping terminals as well as into the circulation system. The distribution system is composed of 1,960 miles of water pipe ranging in diameter from 4" to 60".

Elimination of taste and odor substances from the water.: Softens the water.: Purification to get rid of little particles as well as sanitation to kill viruses and also bacteria, as well as make sure an unsuitable atmosphere for infection and also microorganisms growth throughout the circulation system.

8 Phases of the Wastewater Process Stage One Bar Testing Elimination of large products from the influent to avoid damage to the facility's pumps, shutoffs as well as various other devices. The procedure of treating and also recovering water from wastewater (any kind of water that has actually been used in houses, such as flushing bathrooms, cleaning meals, or showering, as well as some water from commercial usage as well as tornado drains) starts with the assumption that after it is treated it will certainly be tidy enough to reenter the setting.

How Water Purifier For Well Water can Save You Time, Stress, and Money.

According to the EPA, The Clean Water Act (CWA) develops the standard framework for managing discharges of toxins into the waters of the United States and regulating high quality requirements for surface waters. Under the CWA, EPA sets wastewater standards for industry. The EPA has actually additionally created nationwide water quality requirements recommendations for contaminants in surface area waters.

This begins in the aeration container. The primary function of the oygenation tank is to pump oxygen right into the container to encourage the failure of any organic product (and the growth of the microorganisms), in addition to guarantee there is enough time for the natural material to be damaged down.

The 20-Second Trick For Water Purifier For Well Water

This procedure is handled to supply the best problems for you could try these out microbial growth. Dissolved oxygen tracking at this phase of the plant is crucial. Ammonia and nitrate dimensions are typical to determine how reliable the microorganisms are in transforming NH3 to N2.

Phase 5 Second Clarifier Dealt with wastewater is pumped right into a secondary clarifier to enable any remaining natural debris to settle out of cured water flow. As the influent departures the aeration procedure, it flows right into a secondary clarifier where, like the primary clarifier, any kind of extremely tiny solids (or fines) sink to the base of the storage tank.

Part of this turned on sludge is gone back to the aeration container to boost the bacterial focus, help in breeding, as well as visit this site accelerate the breakdown of organic material. The extra is discarded. The water that streams from the second clarifier has actually considerably decreased organic material and ought to be approaching anticipated effluent requirements.

With the boosted focus of bacteria as part of the oygenation phase, there is a need to examine the outgoing effluent for microorganisms presence or lack and to decontaminate the water. This ensures that more than specified focus of bacteria are not released into the environment. Chlorination is the most typical and economical kind of disinfection yet ozone and also UV disinfection are likewise raising in popularity.

7 Easy Facts About Water Purifier For Well Water Shown

After sufficient time, particles comply with each various other imp source and expand right into larger fragments, or, floc, which is vulnerable to clear up in water. This process of floc formation is called flocculation. To assist in the flocculation of fragments, an anionic polymer is added in the blending zone of the cone. Clarification of water is accomplished by the seperation of suspended solids from water by gravity.

The made clear water moves upward gradually, ultimately overlooking the effluent dam to the cone outlet as well as on the to filters for further treatment. The water plant includes a solitary phase lime softening operation to remove solidity. Firmness is brought on by the existence of dissolved bivalent as well as polyvalent steel ions, primarily calcium and magnesium.

This is added both in the clearwell as well as the high service discharge as water goes into the distribution system. 2 mg/l is usually desirable in the plant faucet.